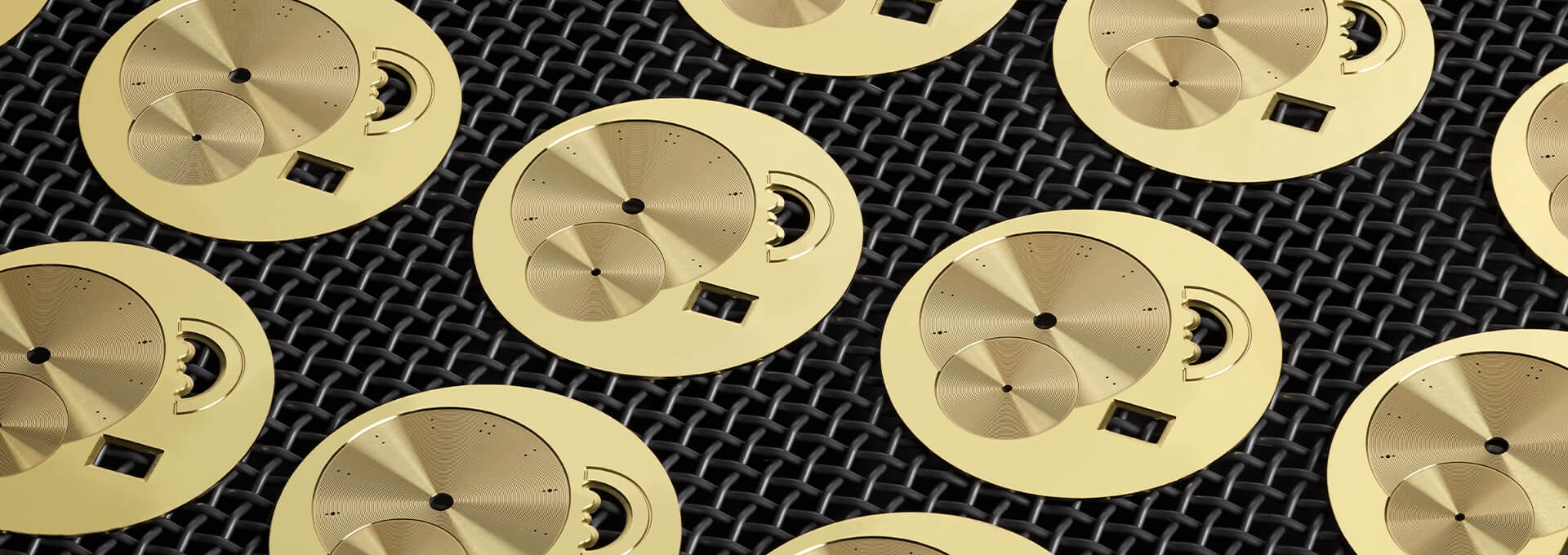

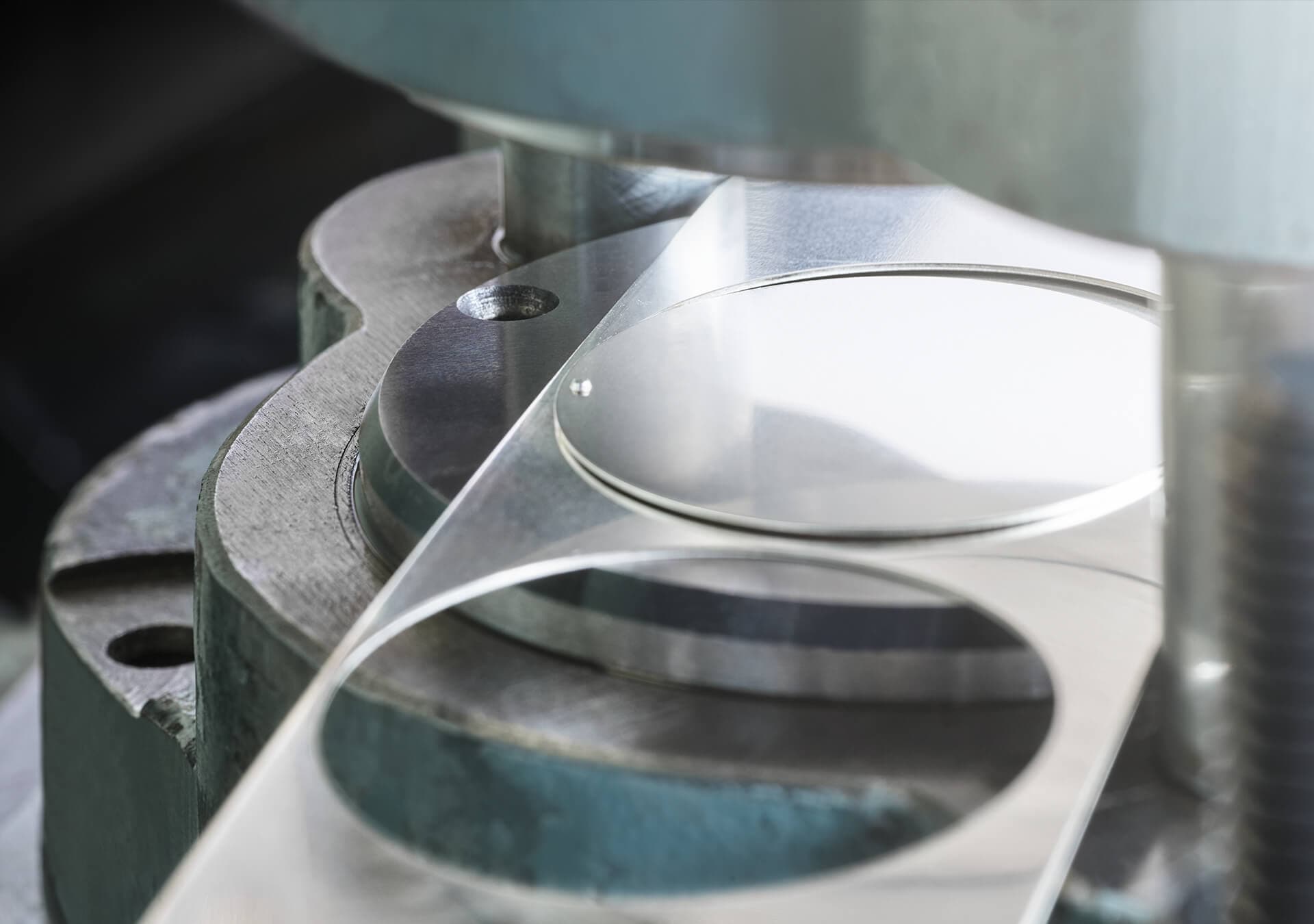

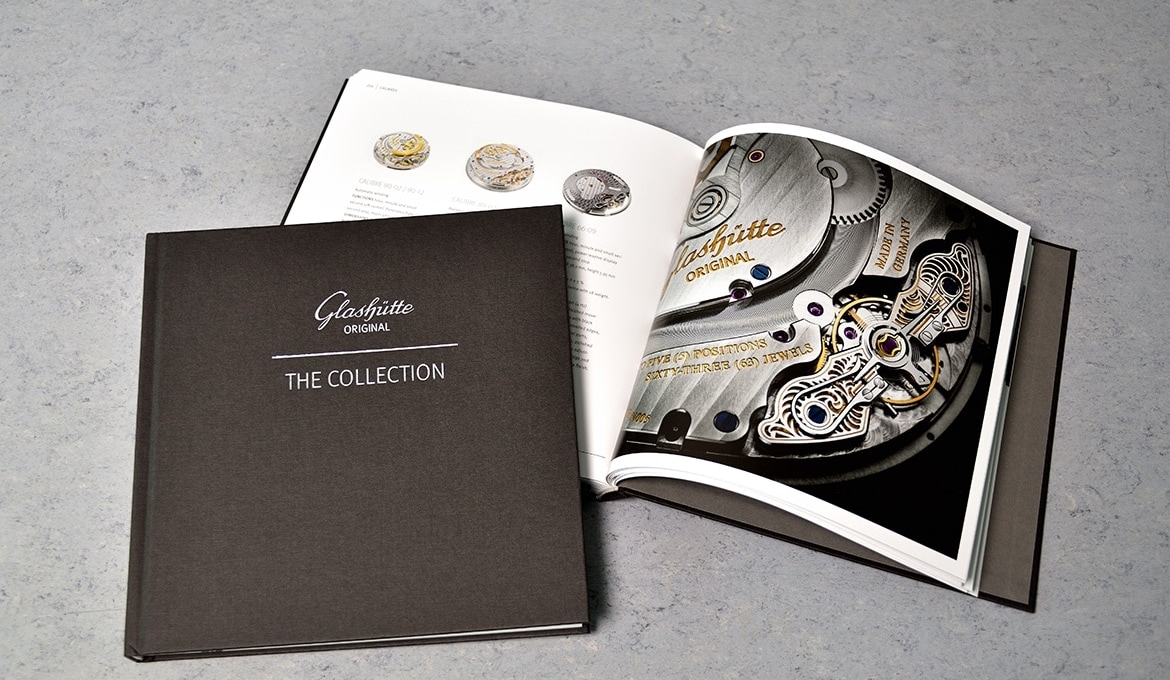

The dial gives a watch its face. What at first glance seems so obviously perfect is one of the greatest challenges in the art of watchmaking. For this reason, in-house dial production is of particular importance: Glashütte Original is one of the few watch manufacturers that produces its own dials by hand. In addition to creativity and experience, extreme care and attention are indispensable in the production of wafer-thin dials and filigree display discs.

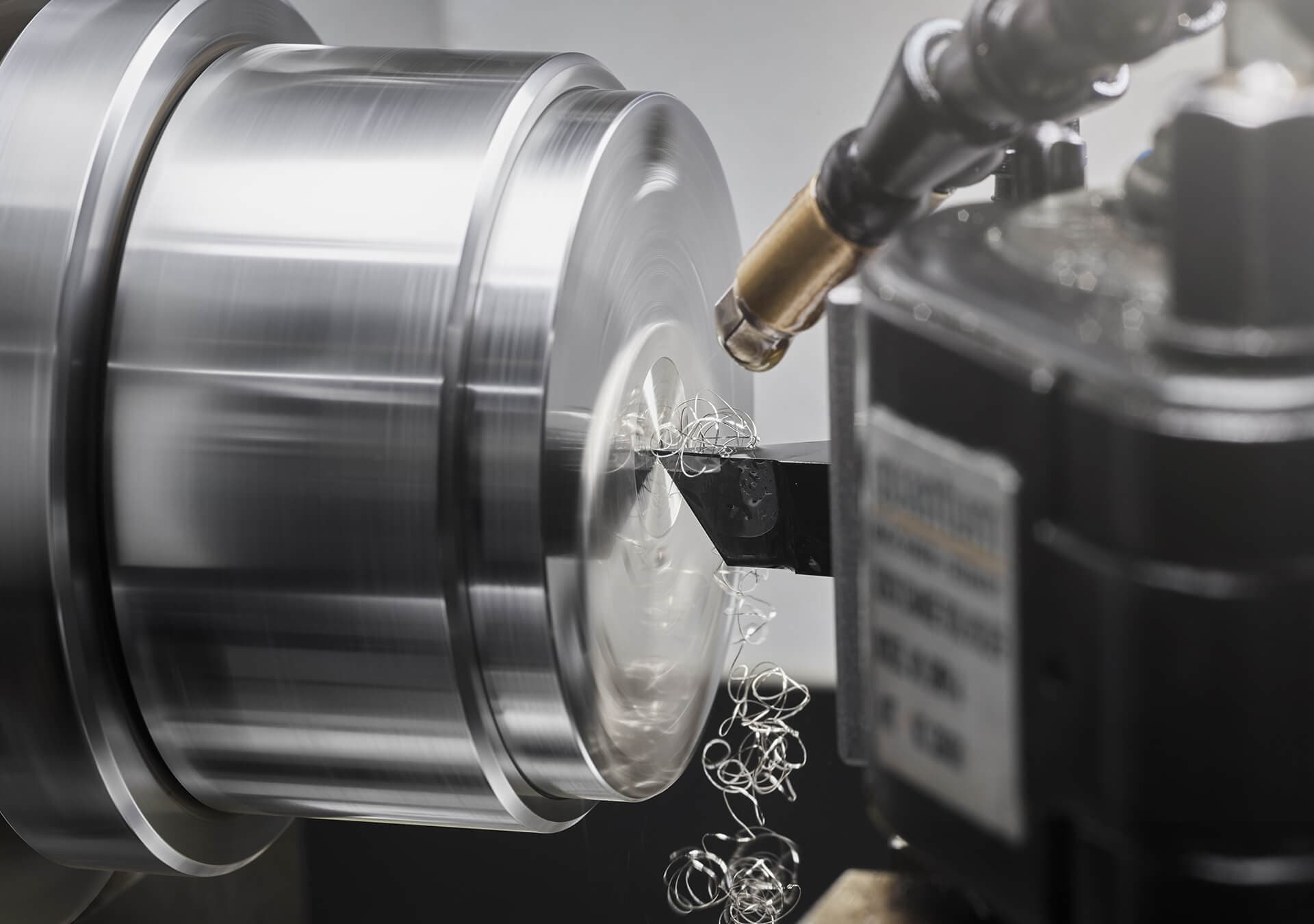

In the new dial manufactory in Glashütte, which was officially opened in June 2025, Glashütte Original has concentrated a high level of expertise that guarantees the high quality and flawless beauty of its dials. Their production involves a large number of individual steps: From the production of the blank and its processing, to the elaborate grinding and polishing of the surface and the diverse and complex finishing processes, numerous hands do their utmost to transform the filigree ‘canvases’ into genuine works of art.